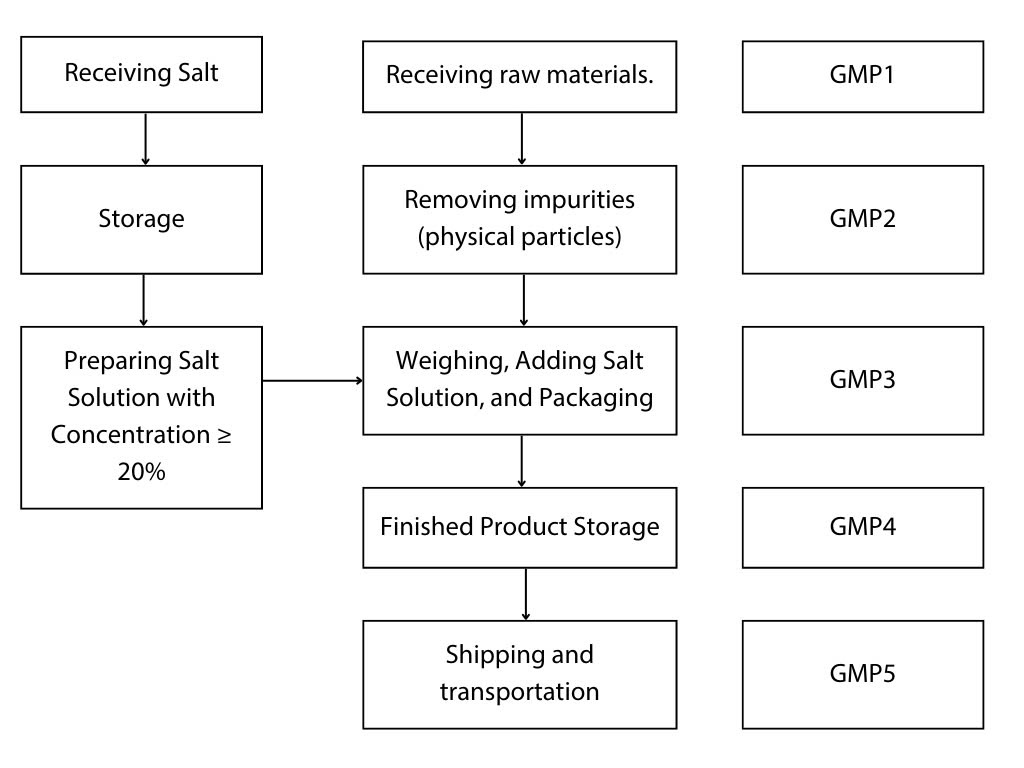

FRESH SALTED BABY SHRIMP PRODUCTION PROCESS

The fresh salted baby shrimp production process includes raw material reception, impurity removal, salting, packaging, and cold storage at a temperature of ≤5°C to ensure the highest quality.

EXPLANATION OF THE TECHNOLOGICAL PROCESS FOR PROCESSING

FRESH SALTED BABY SHRIMP - COLD STORAGE

| Stage | Specifications | Description |

| Receiving raw materials. |

|

|

| Impurity Removal (Sorting by Size) | The salted shrimp must be free of impurities. Whether to sort the shrimp by size depends on the customer's requirements. | Workers manually spread the raw shrimp as thinly as possible on an impurity-sorting table after receiving them to identify and remove impurities such as trash or other species mixed in during harvesting. Unqualified shrimp are also removed. If the customer requests size sorting, we carry it out based on the shrimp's body length, which ranges from 1.8-2.5 cm to 2.0-2.5 cm, as per their specifications. The next step involves moving the shrimp. |

| Weighing, adding salt solution, and packing | The weight of each barrel can be either 18 kg or 20 kg, depending on the specific needs of the customer. Add the salt solution, seal the barrel, and label it. We use salt from an approved supplier that is suitable for consumer use, and the water meets Vietnamese standards. Salt solution concentration > 20%. |

Once the impurities have been removed, place the shrimp into barrels lined with PE bags, ensuring each barrel has a standard weight of 18 kg or 20 kg, or as specified by the order. Next, incorporate the salt solution with a concentration exceeding 20%, making sure the shrimp immerses completely in the saltwater. Seal the PE lining and close the barrel lid, labeling it according to regulations. Prepare two salt solution tanks. Fill the first tank with salt, then add water and stir until the salt dissolves almost completely (50 kg of salt to 150 liters of water). Let it settle for about 30–60 minutes, then transfer it to the second tank to settle for another 30 minutes. Use the clarified solution. |

| Storage | Temperature ≤5°C | Following packaging, a warehouse stores the barrels of salted shrimp at a temperature of approximately 5°C. |

| Shipping and transportation | To prevent tipping during transportation, arrange the barrels of salted shrimp securely on the vehicle. | After packaging, we load the barrels of salted shrimp onto the vehicle for export. |